Floor Tape Blog

The 5S (Plus Safety) Methodology - Sort

As discussed in our previous blog post - The 5S (Plus Safety) Methodology - we're going to be covering each "S" that makes up the methodology.

Today, we'll be covering the first "S" - Seiri (Sort).

Sorting can involve many things, including - but not limited to the following.

- Removing waste - both actual refuse and/or items that don't belong in an area.

- Having management/supervisors continually check/inspect the area to assure everything's in order.

- Assuring any obstacles that could interrupt work are removed.

How can 5S Warehouse assist with this?

- Marking off areas such as "Red Tag Areas" (Items that are ready to be removed)

- Creating specific areas for pallets, pallet jacks, tow motors, and other equipment.

- Making sure all areas you can be and can't be are labeled.

- Having tow motor paths clearly marked.

- And much more!

Our Mighty Line | 5S Warehouse Tape, Angles/T's, Label Protectors, Dots/Arrows/Footprints, and Signs can help you with ALL your sorting needs!

Our next blog post will cover the second "S" - Seiton (Set In Order).

Until then - visit http://www.5SWarehouse.com and request a sample pack today!

The 5S (Plus Safety) Methodology

In one of our previous blog posts - we covered "The Meaning Behind the 5S Name". In the next 6 blog posts - we're going to cover the 5S Methodology piece by piece.

We're even going to up size it one for you to 5S + Safety.

As a workplace organization method - 5S originated from the 5 Japanese words - each beginning with "s" - seiri (sort), seiton (set in order), seiso (shine), seiketsu (standardize), and shitsuke (sustain). And of course the bonus "s" of safety.

All of these contribute to keeping an organized, safe, and productive workplace.

All of these contribute to keeping an organized, safe, and productive workplace.

The mantra of properly organized 5S Methodology is, "A place for everything, and everything in its place."

Imagine how much smoother you could perform your duties - if everything you needed was always in the correct place and ready to use.

In many workplaces - the 5S Methodology is the first lean method implemented.

Our next blog post will cover the first "s" - seiri (sort).

Download our catalogs and see how 5S Warehouse can help with all your 5S needs.

We appreciate your business!

Let Us Lead The Way To Safety

Do you need to identify walkways and exits?

5S Warehouse | Mighty Line 5S Floor Tape Footprints are exactly what you're looking for.

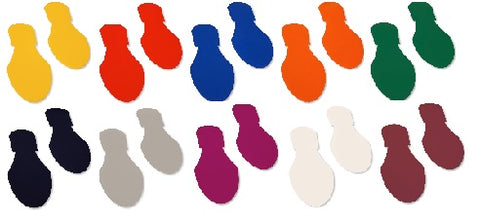

Use different colors of Mighty Line safety floor tape footprints to mark different safety areas (Available in the colors below - and even in Glow In The Dark).

Our floor tape footprints have a three year limited warranty.

Click here - https://www.5swarehouse.com/collections/5s-floor-marking-tape-footprints - for all our available footprints.

5s Warehouse Floor Marking Guide for Lean Manufacturing and OSHA

http://www.slideshare.net/5sWarehouse/5s-floor-marking-tips-and-5s-color-standards

5s Warehouse 5s Floor Marking Guide is the best guide for floor marking tips and 5s Color Standards for your warehouse. This floor marking guide offers tips in making your floor marking OSHA Compliant. Use our durable 5s Warehouse floor tape and floor signs for your warehouse and lean facility today. Visit www.5sWarehouse.com for more details.